I sometimes get the eyeball roll when discussing Predictive Maintenance with prospective leaders of Mechanical Service companies.

Trust me - I get it.

We got the same reaction 20 years ago when we launched our IAQ Diagnostic tool at AirAdvice. The difference is we won’t need a Pandemic to finally validate the Predictive Maintenance model.

There are a few reasons that Predictive Maintenance is going to accelerate to the forefront of our industry…and it won’t take 20 years.

It’s here. It’s happening. And it’s being deployed by your brothers in the industry right now.

5 Critical Factors Driving Predictive Maintenance Adoption

- Industry 4.0’s Groundwork

- Skilled Labor Shortages

- Increasing Client Appetite For Data

- Government Mandates & Supply Chain Issues

- New Analytics Solutions For Small-Mid Sized Buildings

1. Industry 4.0’s Groundwork

As I wrote about in a recent blog, Industry 4.0 documents the adoption of AI-Driven Predictive Maintenance models in the manufacturing industry. We stand to benefit massively from years of their effort.

From enhancing core computing and process controllers to driving stable communications in “noisy” environments to advances in AI and Machine Learning - They got all the tinkering and tooling out of the way for us!

What took Industry 4.0 years to figure out will now only take a matter of months for a mechanical contractor to “leg into” adoption of this technology that has been battle-hardened, tested, and optimized.

2. Skilled Labor Shortages

The hard truth: Our Skilled Labor Shortage needs solutions that are more immediate. For every 1 young tech entering the labor pool, 7 senior techs are retiring. Increasing the flow of youngsters into trade training programs is a long term necessity, but systemic changes like that grind along slowly. They simply won’t provide enough relief in the near term for our businesses.

If we want to see Service GP growth in the next 5 years, we HAVE to work with what we’ve got. That means creating programs that increase the productivity of your existing skilled labor force. This will drive immediate gains while we bring in our future workforce.

A Predictive Maintenance model can simultaneously reduce the disruption of failed and failing machines AND extend the careers and reach of Senior Techs that would otherwise retire. This enables a lean contractor to grow with existing resources. We will be able to do more with less.

3. Increasing Client Appetite For Data

Customers today are increasingly shouting from the rooftops: More Data Please! Having come through the Pandemic, Commercial clients have become more data-sophisticated and, ultimately, demanding.

They want immediate access to their building data. Other disciplines are well ahead of us. Accounting, product development, product management, HR, custom experience, etc. incorporate their data into their delivery. They’re way ahead of us!

It’s time to get out in front with them. It’s time to bring some tangibility for customers to our service delivery, and make our invisible services visible. Our service and sales teams are coming under mounting pressure to meet this data demand.

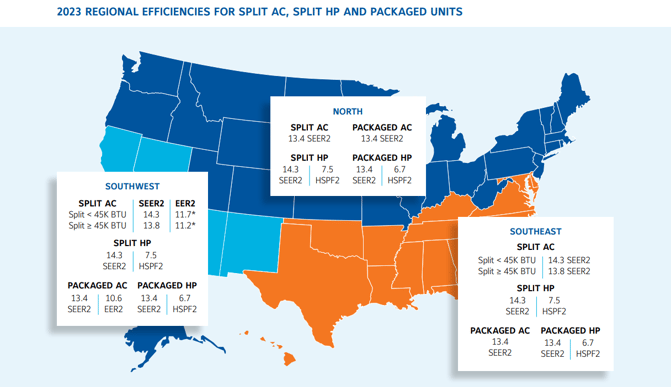

Efficiency standards for single split central air conditioners are still divided into three regions: North, South, and Southwest, with higher SEER2 required for the Southern regions. (Courtesy of Johnson Controls)

4. Government Mandates & Supply Chain Issues

Mandates and Supply Chain combined have created significant delays in packaged unit shipments. What once took a matter of weeks now takes well over 6 months to arrive.

From higher government efficiency mandates to new refrigerants to new mandates/incentives to electrify our economy in the IRA, these all create tremendous pressures on OEMs and their supply chains.

So, an even more rigorous PM program is needed to lengthen the life of aging units. We are seeing numerous examples of Predictive Maintenance, especially the ProActive elements, extending equipment life and helping to justify when a unit needs replacement based on performance data analytics.

5. New Analytics Solutions For Small-Mid Sized Buildings

A few years ago you really needed a Controls-based solution to drive a Predictive Maintenance model. However, thanks to Industry 4.0 and the advent of low cost IoT, less expensive Mechanical-Service-Optimized-Monitoring is now an excellent alternative to more expensive (and complicated) Controls in mid to small sized commercial/manufacturing facilities.

Pulling critical Packaged System Operating Parameters ( Pressures, Temperatures, RH, and power consumption) that aren’t typically captured with Controls allows service teams to focus on machine operation with precision.

Taken together, these factors are driving the rapid transformation in the Mechanical Service Industry. The Predictive Maintenance model is here to stay.

Why? Because it’s the answer to both the needs of the contractor’s for immediate increase in skilled labor productivity AND the client’s demands for more immediate access to building information.

Interested in learning more about how nClarity can help your business? Fill out the form below to get more info about the latest AI-Driven Predictive Maintenance technology.