As we discussed in last week’s blog, we are seeing evidence that many FMs (especially those who are overseeing mission-critical facilities) are fed up with the risk of purchasing descoped, low-priced PM agreements and are interested in exploring new solutions to drive more uptime and reduce costs.

The service contractors that recognize this need and begin to embed Predictive Maintenance solutions powered by IoT HVAC technology into their mission-critical accounts will have a big advantage in their local markets over those that don’t.

Today let’s explore the differences between the:

Traditional PM: Generally 4 standard quarterly visits.

Vs.

Emerging PM: Permanently “gauging up” machines + automated virtual checks every minute.

And how The Emerging PM drives measurable customer benefits The Traditional PM simply cannot.

The Traditional PM (Is It Really “Preventative”?)

The Traditional PM (Is It Really “Preventative”?)

Today’s “Preventative” Maintenance model looks like this:

- Roll the truck 4 times per year

- Perform standard maintenance on all machines, whether it’s warranted or not

- Waste time on machines that don’t need full service

- Hope you can uncover potential sources of degradation and prioritize deeper diagnostic efforts using senses

- Hope you caught everything critical (sometimes you will not)

The Traditional model gives you just 4 unit inspections per year for some percent of the machines that you’re able to get to each quarter.

If a developing issue slips through the cracks and disruption occurs, this is unfortunately when an FM begins to lose trust (and potentially significant amounts of operating revenue).

With the Traditional PM model, all the client has to go off of is your promises.

Not the best source of “Peace of Mind”.

There’s no concrete proof that you do what you say you’re going to do, even if you’re doing a stellar job.

Ironically, the better job you do, the more invisible your services are rendered. If systems are running smoothly, it’s out of sight and out of mind for the FM. They’ll begin to wonder, “What are we paying for here?” and begin to seek out ways to cut maintenance costs by finding a cheaper provider.

The invisibility of the old PM model to the FM is a big part of the reason why HVAC services have become so commoditized.

The contractor and the FM both get the short end of the stick.

Get Cutting-Edge Mechanical Service Insights In Your Inbox

The Emerging PM Model (The Key To Differentiation)

The Emerging PM Model (The Key To Differentiation)

Industry 4.0 and the proliferation of cost-effective IoT solutions in commercial facilities are quickly ushering in a new PM model that is freeing the contractor from service commoditization WHILE driving measurable benefits for building operators.

The Emerging Model: Predictive Maintenance delivered by real-time IoT-based HVAC monitoring.

Here is why Mechanical Service contractors are migrating away from the Traditional PM Model:

We can now collect minute-by-minute HVAC performance data that generates 525,600 inspections per year of every critical unit you’re connected to.

With the nClarity Pulse (reading pressures, power, air side, and more), that comes out to 15,768,000 total inspections of machine performance parameters per machine per year.

It’s like having your best A-tech gauged up and taking readings from each unit 24/7, year-round.

Compare that to the typical 4 inspections per year with The Traditional PM, and it shouldn’t be difficult to imagine how this data can be used to spot developing issues, intelligently perform maintenance, and help you engage with your customers in new ways.

If you enter your local market with this new PM model and you’re vying for contracts against guys that continue to offer an undifferentiated Traditional PM, do you think you would stand a better chance against your competition?

Use Data To Earn Customers For Life

Minute-by-minute HVAC performance data is worth its weight in gold, especially when packaged for client stakeholders (e.g. financial decision-makers and building engineers).

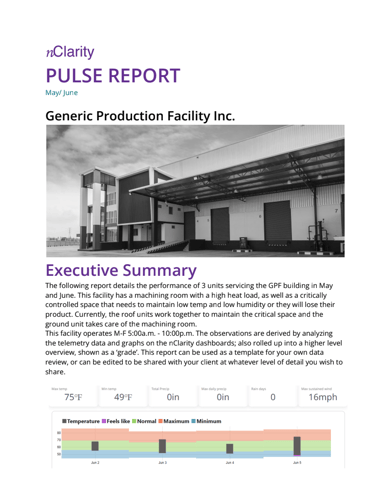

nClarity Pulse Report (Click image to view)

With a report like this, you will have the ability to visit with your customers (with or without Service Operations).

Now you can PROVE your follow-through on promises of:

- More uptime (especially for mission-critical clients)

- Lower operating costs

- Longer equipment life

Imagine if you could actually visit with clients and, using their own data, prove that you are delivering service that meets your commitments and clearly demonstrates your value.

With a report like this, you will likely be able to point out many “wins” that were invisible with the Traditional PM model.

This is the whole point. Real-time IoT-based HVAC monitoring inherently converts all the previously invisible aspects of your stellar service into valuable data insights that can be shared regularly with your clients.

Deliver what FMs truly value, measure it, and document it.

This is how you earn customers for life (and generate case studies that will become your most powerful sales tools).

nClarity’s IoT real-time HVAC monitoring platform is designed to be implemented building by building with a small team, so you can introduce it into your Service Operations in a staged implementation without rocking the boat.

The process looks like this:

- Working with your Operations team, embed IoT monitoring in your accounts one at a time (starting with “friendlies” that have great community profiles)

- Identify low-hanging fruit to drive measurable benefits for the client (uptime, energy savings, etc)

- Build out a reference base in your market to prove the concept and build powerful case studies you can use to gain an unfair sales advantage

If you’re interested in learning more about how to sell Predictive Maintenance (PdM) with IoT real-time HVAC monitoring, you can schedule a call with our team here.